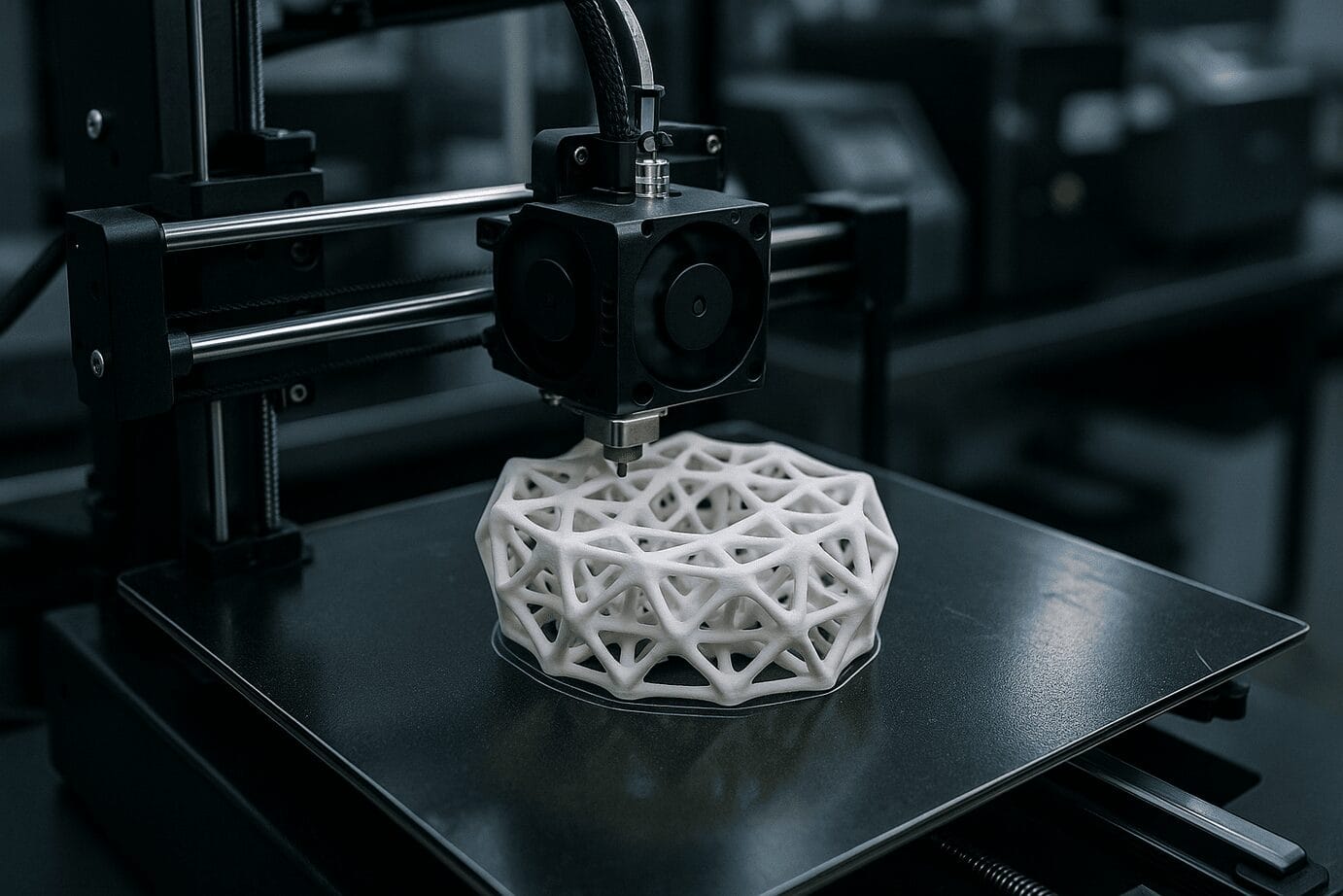

3D printing technology has moved far beyond the novelty phase of plastic hobby parts and tiny figurines. It has become a full-scale industrial force, the kind that quietly works at night while the world sleeps and then suddenly shows up everywhere. Factories use it. Hospitals use it. Car makers swear by it. Space companies rely on it. And the global manufacturing sector is finding itself reshaped in real time.

What Makes 3D Printing Technology So Disruptive?

The central shift is simple but monumental: instead of subtracting material from a block (subtractive manufacturing), 3D printing technology builds items layer by layer. This is where the term additive manufacturing comes from. The shift sounds small, but the consequences ripple across cost structures, logistics, design freedom, energy use, and innovation.

Traditional manufacturing requires molds, machining, tooling, and skilled labor to run large-scale production lines. With modern 3D printing technology, the process looks different. A designer uploads a file. A machine prints the item. The print can be changed instantly, revised, scaled, or personalized. What used to take weeks can now happen in hours.

This new industrial logic bends the rules of production in several ways.

Rapid Prototyping That Accelerates Innovation

Before 3D printing technology became mainstream, prototyping was slow and expensive. Engineers needed molds or machined parts. A single prototype could take weeks. Revising it meant starting again from zero.

Now, designers iterate like software developers. They tweak designs. They print a new version. They test, adjust, reprint, and move forward. Companies no longer lose momentum waiting for prototypes to arrive from distant suppliers.

This means:

• Faster research cycles

• Reduced engineering costs

• Higher-quality products

• More room for creative experimentation

Every industry that relies on prototyping—from footwear to aerospace—benefits from this acceleration. Even the giants like NASA and SpaceX use rapid iterations enabled by 3D printing technology to perfect rocket components.

External reference:

https://www.nasa.gov/directorates/stmd/space-tech-research/3d-printing/

Unmatched Design Freedom

Manufacturing used to demand conformity to machine limitations. Complex shapes cost more. Curves required special tooling. Hollow structures were practically impossible.

3D printing technology flips that logic. Complex shapes cost nothing extra. Hollow structures? Easy. Lattice designs? Standard procedure. Integrated parts that traditionally needed multiple components can now be printed as a single piece.

This opens new dimensions for engineers:

• Lighter yet stronger structures

• Ergonomic, organic shapes

• Customizable components

• Lower material waste (helpful for sustainable production)

Design freedom is one of the most underrated but transformative aspects of additive manufacturing. Limitations that engineers once accepted without question are dissolving one by one.

Customization at No Extra Cost

Mass production made products cheap but uniform. Customization was expensive—until now.

With 3D printing technology, every item can come out differently without slowing down the line. This ability is critical for industries such as:

• Medical implants

• Dental aligners

• Prosthetics

• High-end consumer electronics

• Automotive interiors

• Customized sporting equipment

A production line might print a thousand items, each slightly different, at no additional cost. This level of customization blends digital fabrication with advanced design, unlocking products that fit individuals instead of averages.

Revolutionizing Supply Chains Worldwide

One of the biggest industrial shifts caused by 3D printing technology has nothing to do with design. It’s happening behind the scenes, deep inside global logistics.

Traditional manufacturing relies on large centralized factories. Products travel through warehouses and distribution centers to reach customers. This model requires forecasting, inventory management, and shipping—activities prone to delays and inefficiencies.

3D printing technology allows for flexible, on-demand production near the point of use. Companies no longer need to store huge inventories of spare parts. They can keep digital files instead and print parts when needed.

This shift:

• Reduces warehouse costs

• Minimizes shipping emissions (supporting sustainable production)

• Strengthens supply-chain resilience

• Protects companies from geopolitical disruptions

Airbus is already printing aircraft parts at distributed facilities. The U.S. military prints field-ready components on forward bases.

External reference:

https://www.airbus.com/en/innovation/technical-capabilities/additive-manufacturing

From Plastics to Metals to Concrete: Material Advances Expand Possibilities

Early 3D printers were limited to plastics. Today, materials have evolved dramatically. 3D printing technology now works with:

• Industrial metals (titanium, stainless steel, aluminum)

• Bio-compatible materials (for medical implants)

• High-strength polymers

• Ceramics

• Food-grade materials

• Composite materials

• Concrete for buildings

• Carbon fiber-infused filaments

This expansion allows additive manufacturing to penetrate sectors once believed too rugged or high-performance to adopt layer-based fabrication.

Metal 3D Printing

Metal printers can produce turbine blades, engine parts, custom tools, and lightweight aerospace components that outperform traditionally machined parts.

Concrete 3D Printing

Construction firms are exploring digital fabrication of houses, bridges, and shelters. Concrete printing cuts construction time, reduces labor shortages, and minimizes material waste.

External reference:

https://www.iconbuild.com

Industrial Automation Meets Additive Manufacturing

In modern factories, 3D printing technology fits naturally into the broader movement toward industrial automation. Automated 3D print farms—rows of synchronized printers working 24/7—already exist.

Robots load and unload print beds. Sensors monitor thermal fluctuations. AI analyzes print quality. Entire production lines run with minimal human intervention.

This convergence of automation and additive manufacturing creates:

• Full-time production without downtime

• High repeatability

• Predictable quality control

• Significant labor cost reduction

As printers become faster and larger, these automated print farms are expected to rival traditional factories in output volume.

Sustainable Production: Less Waste, Fewer Emissions

Traditional manufacturing cuts away material, often wasting more than half. 3D printing technology uses only what is necessary.

This resource efficiency supports sustainable production in several ways:

• Lower raw material usage

• Reduced emissions from shipping (thanks to local fabrication)

• Longer component lifespans through easy repair and reprinting

• Ability to recycle some materials directly for reprinting

Studies show that additive manufacturing can reduce material waste by up to 90% in certain aerospace applications. This is a major win for sustainability goals across industries.

External reference:

https://www.energy.gov/eere/amo/additive-manufacturing

Industries Transforming the Fastest

Aerospace

Lightweight components, complex geometries, and rapid prototyping make aerospace a perfect match for 3D printing technology. Engines, brackets, internal cabin parts, and satellite structures are already printed routinely.

Automotive

Carmakers rely on additive manufacturing for custom tooling, spare parts, and even end-use components. Custom cars, motorsport applications, and electric vehicle startups use 3D printing technology to accelerate innovation cycles.

Healthcare

Dental aligners, prosthetics, bone implants, and surgical models are now standard outputs of digital fabrication. Each item is customized to the patient, improving outcomes dramatically.

Consumer Products

Sneakers, eyewear, luxury furniture, and high-performance sports gear are increasingly tailored through 3D printing technology.

Construction

Large-scale printers build walls, shelters, and houses far faster than traditional methods. This field is young but expanding quickly.

Economic Impact: Lower Costs, Faster Production

The economics behind 3D printing technology are shifting rapidly. While printers were once expensive, prices have been dropping and capabilities rising.

Benefits include:

• Lower cost per part for low-volume production

• Reduced tooling expenses

• Minimal setup time

• Faster turnaround

• Less labor required

• Less material waste

For niche industries, low-volume markets, and custom products, 3D printing often beats traditional manufacturing outright. As machines get faster and materials improve, the break-even point against mass-production methods shifts further in favor of additive manufacturing.

Challenges Slowing Down Adoption

Despite its power, 3D printing technology faces challenges that must be addressed:

Speed Limitations

Printing is still slower than traditional molding for mass production. However, new technologies like binder jetting and multi-laser systems are rapidly closing the gap.

Material Costs

Although materials are diversifying, some high-performance filaments and metal powders remain expensive.

Regulatory Hurdles

Medical devices, aerospace components, and safety-related parts require strict certification.

Skill Gaps

Designing for additive manufacturing requires new expertise—engineers must think like sculptors rather than machinists.

Printer Maintenance

Industrial machines require careful calibration and monitoring.

Even with these challenges, industry momentum continues to surge.

The Future: When 3D Printing Technology Becomes Mainstream Manufacturing

The next decade will bring massive industrial shifts powered by 3D printing technology. Trends to expect include:

• Hybrid factories mixing additive and traditional manufacturing

• Ultra-fast printers scaling to mass production

• New printable materials (glass, electronics, bio-organics)

• AI-optimized designs impossible for humans to conceive

• Decentralized micro-factories near customers

• Printable electronics integrated into everyday objects

Eventually, the distinction between design and manufacturing will fade. Products will be created as digital blueprints and materialize on demand, anywhere in the world.

External Sources Used

https://www.nasa.gov/directorates/stmd/space-tech-research/3d-printing/

https://www.airbus.com/en/innovation/technical-capabilities/additive-manufacturing

https://www.iconbuild.com

https://www.energy.gov/eere/amo/additive-manufacturing

Conclusion

3D printing technology is no longer the future—it is the present. Its impact on prototyping, customization, supply chains, sustainability, and industrial innovation makes it one of the most transformative technological shifts since the rise of automation itself. As it merges with industrial automation, new materials, and global-scale connectivity, manufacturing becomes more flexible, more innovative, more sustainable, and more decentralized.

The world is moving toward a model where ideas flow instantly from imagination to object. The next industrial revolution won’t roar with factories full of smoke and steel. It will hum quietly, layer by layer, as 3D printing technology redefines how humanity builds the world around it.

More from The Daily Mesh:

- Journalism in the Age of AI Fact-Checking: Navigating Truth, Tools and Trust

- Who Is Mira Nair Today: A Deep Dive into the Life and Career of Mira Nair

- How to Tell If You Have an Internet Speed Issue (and What to Do)